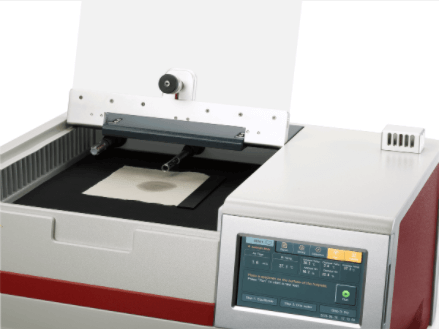

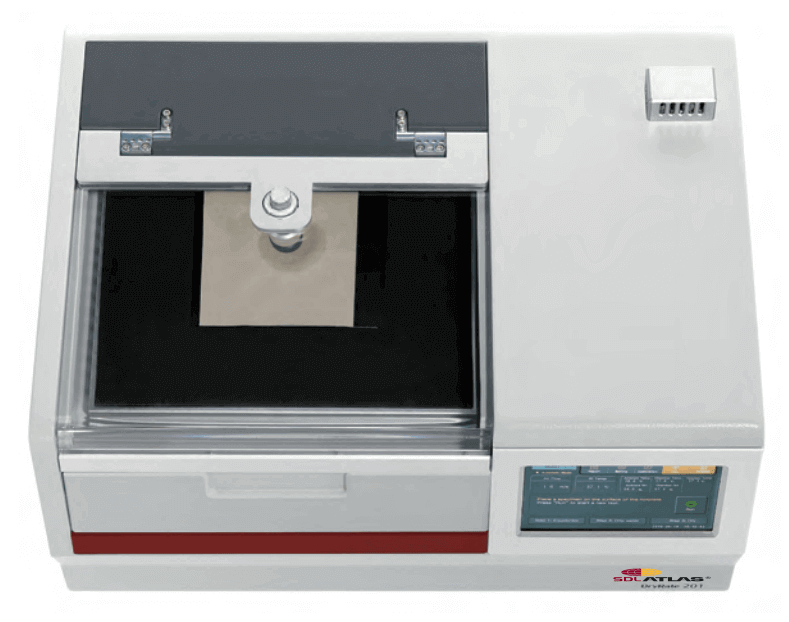

DryRate 201

SDL Atlas

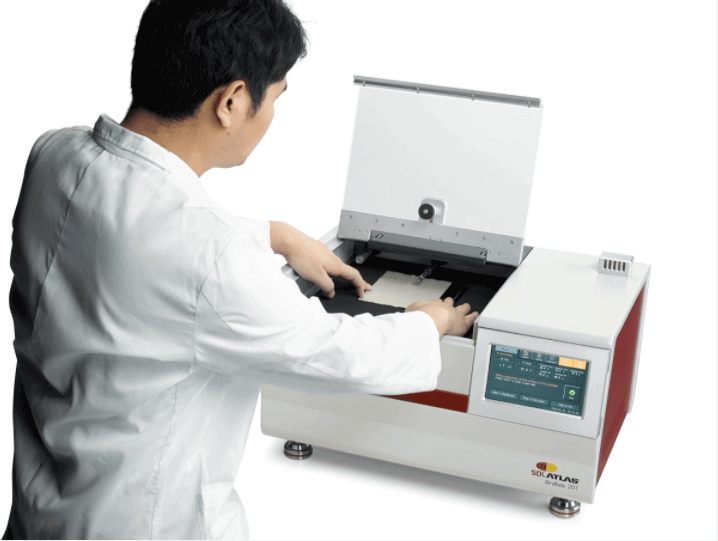

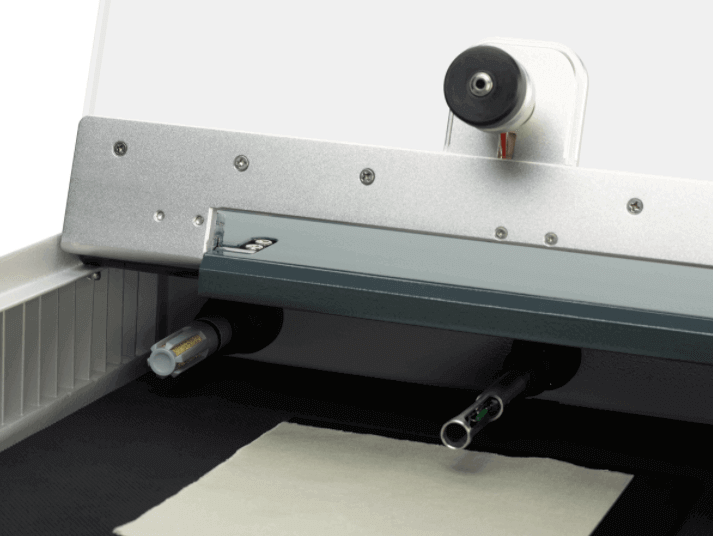

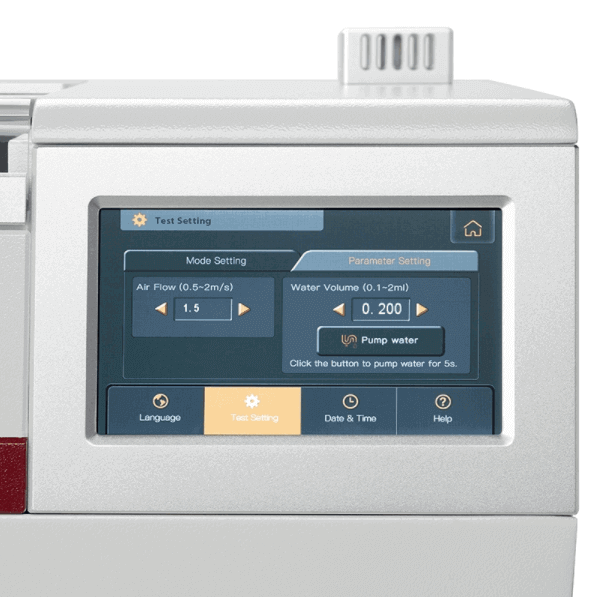

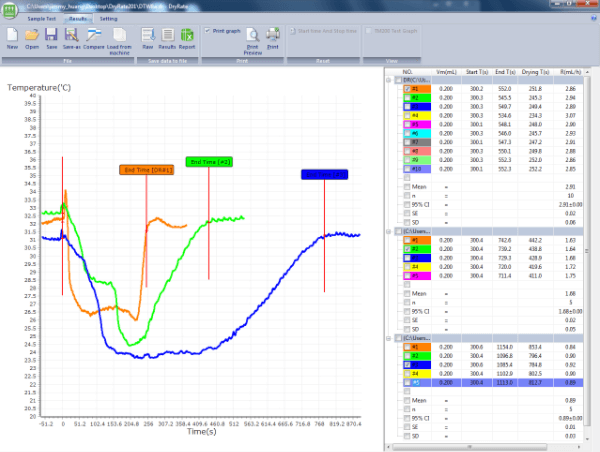

The SDL Atlas DryRate 201 or Drying Rate Tester for AATCC Test Method 201 is a fully automated and advanced instrument with a heated metal plate, which simulates human skin starting to perspire at 37°C, that determines the drying rate based on evaporation rate from the fabric. The testing principle is based on the principle of a wetted fabric against a heat source with air flow, the evaporation of water will remove heat to reduce the surface temperature. Detecting the temperature of the fabric surface accurately determines whether the textile has become completely dry. Closed-loop control system (heated metal plate and air flow) secures consistent test conditions. Testing conditions are constantly monitored by the built-in anemometer (air flow sensor) and infrared thermocouple probe. For the fully automated testing mode, the operator simply places the sample in the test area, and the instrument will automatically run the test. Water dispensing initiates automatically. The operator can change the amount of water and air flow through the testing parameters. The manual test mode allows manual water dosing as described in the AATCC 201 Test Method. The test materials includes multifiber, cork liners, abradents, phenolic yellowing, detergents, ballasts and crocking fabric.

Click here to visit the product page.